Schluter -DITRA & DITRA-XL (Membrane)

Price range: $127.08 through $664.85

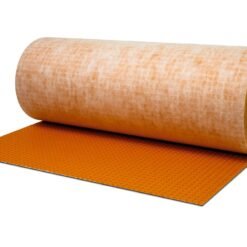

Schluter®-DITRA and DITRA-XL are specifically designed for ceramic and stone tile installations. DITRA and DITRA-XL provide uncoupling to prevent cracked tile and grout. Made of polyethylene, DITRA and DITRA-XL serve as a waterproofing layer that protects moisture-sensitive substrates, such as plywood/OSB. Free-space on the underside of the matting provides a route for excess moisture and vapor to prevent damage to the tile layer above. DITRA and DITRA-XL perform all these functions while still providing adequate support/load distribution for the tile covering.

- Provides uncoupling, waterproofing, vapor management, and heavy load distribution to ensure the durability and integrity of tile installations

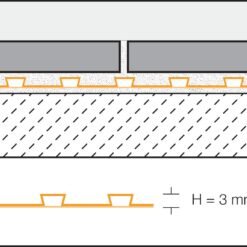

- DITRA has a nominal 1/8″ (3 mm)-thickness which minimizes tile assembly thickness and reduces transitions to lower surface coverings

- DITRA-XL is 5/16” (7 mm)-thick to create an even transition between typical 5/16” (7 mm)-thick tile and 3/4” (19 mm)-thick hardwood flooring

- DITRA-XL allows for ceramic tile application over single layer plywood/OSB subfloors on joists spaced at 24” (610 mm) o.c.

- Can be installed on top of concrete, plywood, OSB, gypsum, existing vinyl floors, structural planks, sub-floors, and radiant heated floors

- Features a grid structure of square cutback cavities and an anchoring fleece laminated to the underside which is bonded to the surface of the substrate and prevents thin-set from filling the cavities

- Quick and easy to install; few tools required and ready to receive tile immediately.Download Technical Info

Download Data Sheet

Reviews

There are no reviews yet.