EPOXI SYSTEM ICASA

$175.00 – $270.00Price range: $175.00 through $270.00

The EPOXI SISTEM FLOOR-225 is a 2-component high gloss epoxy coating designed to be used in industrial floors and areas of wet process, which are exposed to constant water, grease and oil, as well as dairies, beverages, food industries, industrial kitchens, hangars, garages, among others.

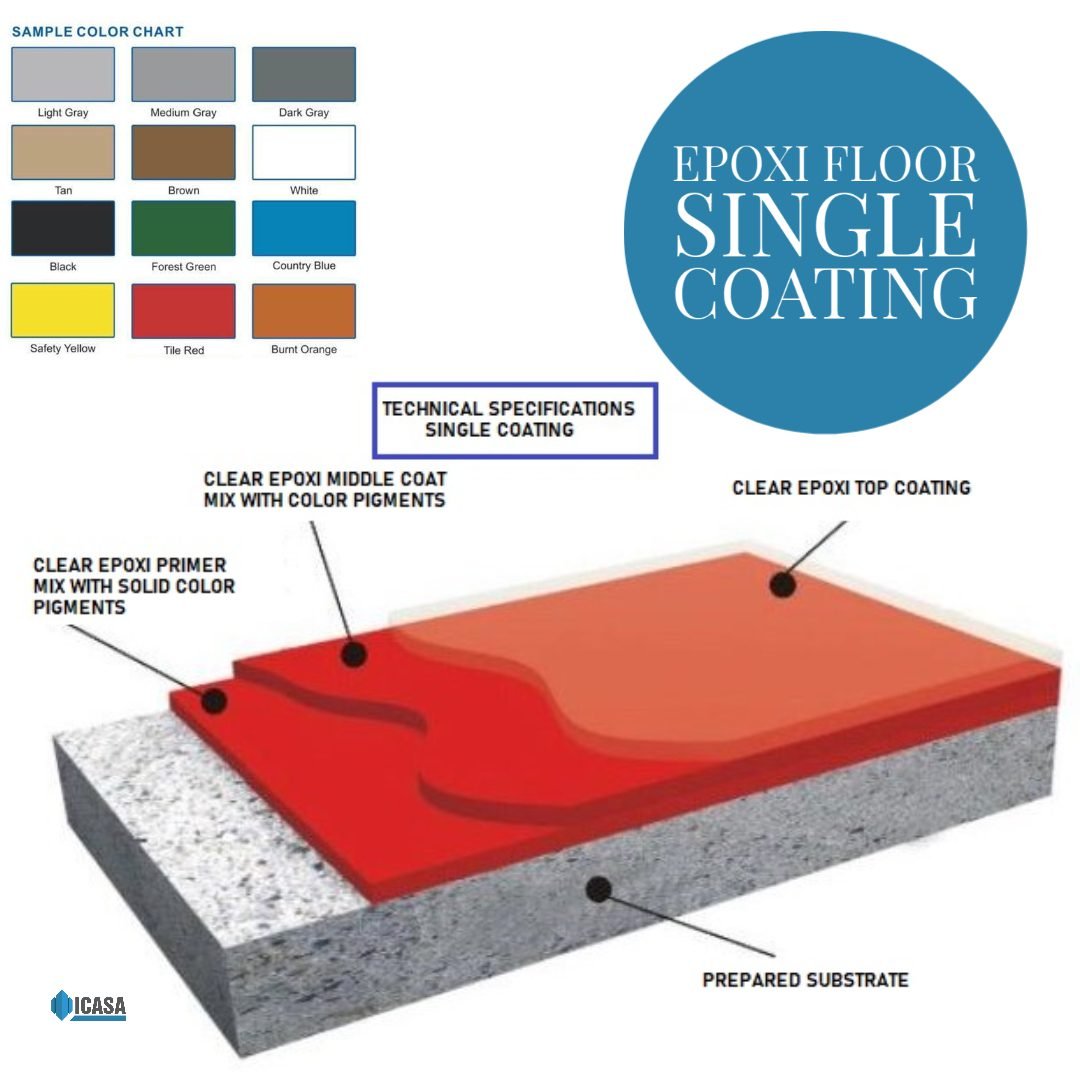

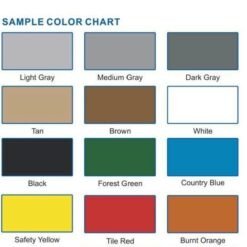

TECHNICAL SPECIFICATIONS

SINGLE COATING

This is a layer of 100% solid epoxy resin, approximately 16 -18 mils thick which provides a surface without porosity and easy cleaning. Its capacity to be a completely sealed layer, with no cracks or pores, prevents the housing and cultivation of bacteria, making it ideal for pharmaceutical and food industries solution.

This system is resistant to abrasion, corrosion and wear. The epoxy coating provides the versatility of application in various colors that accentuate the image that our customers are seeking.

Method of Application:

For applications over new concrete, it must have at least 28 days of draining in order to achieve its curing and resistance.

The maximum humidity of the substrate must be less than 4%.

In order to check humidity, a moisture meter may be used or apply the test of plastic. which consists of placing a piece of plastic on the surface for 24h. If condensation appears under the plastic, moisture or vapor transmission is present.

Substrates with greater than or equal to 4 % moisture need to use a vapor barrier.

Mixture:

Pour into a clean, dry container, 2 parts of product A with 1 part of product B, strictly maintaining its proportions.

We recommend using a low-speed electric drill (300-400. Rpm).

Mix well to achieve homogeneity, for about 3 minutes.

To make non-slip coatings or epoxy mortars thicker consult our technical department, to indicate the amount of silica or quartz sand required

Cautions:

The product contains substances that if being in contact with the skin and/or inhaled for prolonged periods may cause serious health damage.

The information contained in this document was given in good faith, based on the experience and knowledge that ICASA COMMERCE, LLC has about the product as long as they have stored, handled and applied it under normal conditions in accordance with the instructions and recommendations of ICASA COMMERCE, LLC.

The information contained herein does not exonerate the user to make the necessary testing of products in places where it will be applied to obtain the best results.

Storage:

2 years in tightly sealed containers, in a dry and cool environment

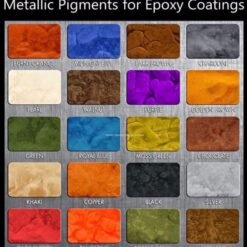

TECHNICAL SPECIFICATIONS

METALLIC

Pure Metallic Floor Coating is 100% solids, 2 component epoxy. It is a specially formulated epoxy with a pearlescent metallic pigment. It is roller or squeegee applied to your floor.

This coating requires a primer coat, metallic 100% solids epoxy base coat with effects kit, and a UV resistant urethane or 100% solids epoxy clear-coat.

The finished look is a smooth, glass-like finish that has a unique and subtle reflective sparkle. No two floors will ever look the same.

There are endless creative techniques that can be used to create a style that you can call your own.

Some of our customers say Pure Metallic Floors resemble moon craters, a lava lamp, lighting strikes, marble countertops, shimmery glitter paint and they appear three dimensional.

Method of Application:

For applications over new concrete, it must have at least 28 days of draining in order to achieve its curing and resistance.

The maximum humidity of the substrate must be less than 4%.

In order to check humidity, a moisture meter may be used or apply the test of plastic. which consists of placing a piece of plastic on the surface for 24h. If condensation appears under the plastic, moisture or vapor transmission is present.

Substrates with greater than or equal to 4 % moisture need to use a vapor barrier.

Mixture:

Pour into a clean, dry container, 2 parts of product A with 1 part of product B, strictly maintaining its proportions.

We recommend using a low-speed electric drill (300-400. Rpm).

Mix well to achieve homogeneity, for about 3 minutes.

To make non-slip coatings or epoxy mortars thicker consult our technical department, to indicate the amount of silica or quartz sand required.

Cautions:

The product contains substances that if being in contact with the skin and/or inhaled for prolonged periods may cause serious health damage.

The information contained in this document was given in good faith, based on the experience and knowledge that ICASA COMMERCE, LLC. has about the product if they have stored, handled and applied it under normal conditions in accordance with the instructions and recommendations of ICASA COMMERCE, LLC.

The information contained herein does not exonerate the user to make the necessary testing of products in places where it will be applied to obtain the best results.

Storage:

2 years in tightly sealed containers, in a dry and cool environment

TECHNICAL SPECIFICATIONS

MORTAR

Is a folder from 1/8 to ¼ of an inch, produced from polymers and silica sand, which provides a non-porous surface easy to clean and high resistance to impacts.

It prevents the hosting and accommodation of bacteria, ideal for areas of packaging and processing products, as well as laboratories and hospitals.

This system is resistant to abrasion as well as the constant spilling of acids and strong chemicals.

The epoxy provides the finishes versatility in various colors that allow the image that the company is seeking.

Method of Application:

For applications over new concrete, it must have at least 28 days of draining in order to achieve its curing and resistance.

The maximum humidity of the substrate must be less than 4%.

In order to check humidity, a moisture meter may be used or apply the test of plastic. which consists of placing a piece of plastic on the surface for 24h. If condensation appears under the plastic, moisture or vapor transmission is present.

Substrates with greater than or equal to 4% moisture need to use a vapor barrier.

Mixture:

Pour into a clean, dry container, 2 parts of product A with 1 part of product B, strictly maintaining its proportions.

We recommend using a low-speed electric drill (300-400. Rpm).

Mix well to achieve homogeneity, for about 3 minutes.

To make non-slip coatings or epoxy mortars thicker consult our technical department, to indicate the amount of silica or quartz sand required.

Cautions:

The product contains substances that if being in contact with the skin and/or inhaled for prolonged periods may cause serious health damage.

The information contained in this document was given in good faith, based on the experience and knowledge that ICASA COMMERCE, LLC. has about the product as long as they have stored, handled and applied it under normal conditions in accordance with the instructions and recommendations of ICASA COMMERCE, LLC

The information contained herein does not exonerate the user to make the necessary testing of products in places where it will be applied to obtain the best results.

Storage:

2 years in tightly sealed containers, in a dry and cool environment

TECHNICAL SPECIFICATIONS

FLAKES

Epoxy Floor with Flakes is 100% solids, 2 component epoxy. It is a special designed for decorative applications, such as garage floors .Color flakes are produced from pigments, resin, filler, and additives, are through-colored, random in shape, and available in a wide array of colors to provide unique texture and color to coated surfaces.

Method of Application:

For applications over new concrete, it must have at least 28 days of draining in order to achieve its curing and resistance.

The maximum humidity of the substrate must be less than 4%.

In order to check humidity, a moisture meter may be used or apply the test of plastic. which consists of placing a piece of plastic on the surface for 24h. If condensation appears under the plastic, moisture or vapor transmission is present.

Substrates with greater than or equal to 4 % moisture need to use a vapor barrier.

Mixture:

Pour into a clean, dry container, 2 parts of product A with 1 part of product B, strictly maintaining its proportions.

We recommend using a low-speed electric drill (300-400. Rpm).

Mix well to achieve homogeneity, for about 3 minutes.

To make non-slip coatings or epoxy mortars thicker consult our technical department, to indicate the amount of silica or quartz sand required

Cautions:

The product contains substances that if being in contact with the skin and/or inhaled for prolonged periods may cause serious health damage.

The information contained in this document was given in good faith, based on the experience and knowledge that ICASA COMMERCE, LLC. has about the product as long as they have stored, handled and applied it under normal conditions in accordance with the instructions and recommendations of ICASA COMMERCE, LLC.

The information contained herein does not exonerate the user to make the necessary testing of products in places where it will be applied to obtain the best results.

Storage:

2 years in tightly sealed containers, in a dry and cool environment

Be the first to review “EPOXI SYSTEM ICASA” Cancel reply

Related products

Merkrete

Peygran

AC Vents - Linear Diffusers

Reviews

There are no reviews yet.